![]()

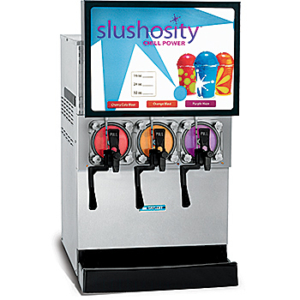

Dispense a light, fluffy, high overrun slush product in a pressurized system from this Taylor C303 modular, counter-top freezer. Optional nonpressurized system produces a wetter, lower overrun slush. Air is discharged out the top of the unit to accommodate tight counter space. Optional cart converts the unit to a self-contained floor model, and provides storage for the syrup.

Taylor C303 Frozen Carbonated Beverage (FCB) Freezer Three Flavors Features

Dispense a light, fluffy, high overrun slush product in a pressurized system from this modular, counter-top freezer. Optional nonpressurized system produces a wetter, lower overrun slush. Air is discharged out the top of the unit to accommodate tight counter space. Optional cart converts the unit to a self-contained floor model, and provides storage for the syrup.

Freezing Cylinder

Three, 7 quart (6.6 liter).

Dispensing Door

Clear plastic dispensing doors allow customers to see slush being made. Self closing draw handles are standard. Round dispensing nozzle conveniently fits the hole in domed lids.

Indicator Lights/Audible Alarm

Lights illuminate and audible alarm sounds to indicate loss of CO2, water or syrup on the affected freezing cylinder. The other flavors will continue to operate when one loses syrup. A snooze feature may be activated to silence the alarm for 30 minutes.

Automatic Defrost

Programmable defrost cycles allow the operator to select the time and frequency for defrosting each freezing cylinder independently. The defrost light flashes to warn customers not to draw product from the side that is being defrosted. At the end of the defrost cycle, the freezing cylinder automatically returns to the freeze-down mode.

Power Saver

During extended no-use periods, the Power Saver feature may be programmed for either Standby or Rest Mode. Standby Mode maintains product in freezing cylinder between 35 & 40°F (1.6 & 4.4°C) for quickest return to serving product. Rest Mode shuts down the refrigeration system for the most energy savings. Start and end times may be programmed independently for seven cycles.

Sure SetTM Flow Control

Automatically maintains brix settings by compensating for fluctuations in water, CO2, and syrup pressures. Water flow is preset at the factory.

Electronic Viscosity Control

SlushtechTM is standard with our exclusive microprocessor based universal control which regulates refrigeration by measuring product viscosity.

Air Filter

Removable, cleanable air filter helps keep condenser clean for optimal refrigeration system performance.

Merchandising

LED display backlights translight and illuminates clear dispensing doors to draw customer attention. This display provides energy efficient, even, consistent lighting.

Preventative maintenance programs are available through your local Taylor distributor.

Continuing research results in steady improvements; therefore, these specifications are subject to change without notice.

Taylor C303 Frozen Carbonated Beverage (FCB) Freezer Specifications

Electrical

One dedicated electrical connection is required. See the Electrical chart for the proper electrical requirements. Manufactured to be permanently connected. Consult your local Taylor distributor for cord & receptacle specifications as local codes allow.

Beater Motor

Three, 1/6 HP.

Refrigeration System

One, 18,000 BTU/hr compressor (nominal rating). R404A.

(Actual BTUs will vary based on application.)

Carbonation System

Dedicated remote carbonation system. Syrup, CO2(1/4” MFL) and water (3/8” MFL) fittings connect at the rear of the machine. Requires separate 115 volt, 60Hz, 1 phase electrical connection, NEMA 515P.

Potable Water Pressure

Minimum 25 PSI for proper operation of carbonation system.

Air Cooled

Minimum Clearance: 3” (76 mm) around all sides, and 12” (305 mm) on the top of the unit. Minimum air clearances must be met to assure adequate air flow for optimum performance.

Water Cooled

Water inlet and drain connections at rear 3/8” FPT provided.

Taylor C303 Frozen Carbonated Beverage (FCB) Freezer Options

- Syrup Tank Fittings

- Syrup Storage Cart: Includes shelves for storing BIB FCB syrups and mounting BIB pumps (not included).

Dimensions

Width: 23-1/8” (587 mm)

Depth: 35” (889 mm)

Two Heights Available: 32-1/8” (816 mm) or 25-1/2” (648 mm)